Recently, with the successful delivery of its first 40,000-cubic-meter MGC carrier, Nantong CIMC Sinopacific Offshore & Engineering Co., Ltd. (hereinafter "SOE" or the company) has taken another firm step in the construction of new clean energy vessels. Currently, building on its accumulated technical expertise and construction reputation in the liquefied gas carrier sector, the company has successfully secured the trust of international shipowners including Exmar, Capital Gas, and Amon Gas, holding a total of 10 MGC carrier orders.

Refined Construction, Breaking New Ground: Building Core Strengths Through Continuous Improvement

Facing market demands and construction challenges, SOE treats MGC carrier projects as a key opportunity to enhance its capabilities. The company has deeply integrated the production principles of precision, standardization, and workflow rhythm into the entire MGC carrier construction process, successfully achieving efficiency gains across the entire chain from block fabrication to vessel launch.

During the construction of the 40,000m³ MGC carrier series, by quickly finalizing drawings and processes for the lead vessel and scientifically planning the dock layout, the company established an efficient parallel workflow of "one vessel in block erection, one in unit assembly, and one in block fabrication," ensuring an orderly production sequence. For the newly undertaken Type A cargo tanks, the project team planned ahead and optimized procedures, completing structural work and entering the coating/insulation phase one month before docking, and starting Type A tank erection just one month after docking. At the same time, the company fully implemented a unit assembly strategy, moving engine room unit installation to the pre-assembly stage, significantly increasing completeness at launch and setting a new record by achieving generator commissioning readiness in just two weeks.

This series of effective improvements yielded clear results. The dock period for the 40,000m³ MGC carrier was successfully reduced from the initially planned 135 days, through ongoing optimization to 120 and 110 days, and finally to just 95 days for the S1085 project! This effective shortening of the dock cycle freed up a valuable building berth. This not only created space for the order activation and continuous construction of the subsequent Capital series vessels but also provided a crucial condition for securing the more technically challenging order for Amon Gas's 51,000m³ MGC carriers.

The construction of the Type A tanks deserves special mention. This cargo tank type represents a significant expansion of SOE's capabilities beyond its existing Type C and Type B tank technologies, while also marking entry into a new and challenging area. Without prior mature experience to follow, the project team started from the ground up, dedicating themselves to research and overcoming the constraints of the company's existing hardware. They successfully executed the complex operation of lifting a Type A semi-tank for the first time. It was through this determined, problem-solving approach and meticulous planning that SOE achieved the industry's shortest construction cycle for the first vessel equipped with Type A tanks.

Partnering for Shared Success: Defining a New Model of Win-Win Collaboration

SOE firmly believes that the creation of high-quality vessels depends not only on its own dedicated construction efforts but also on close collaboration with partners such as shipowners and suppliers. This commitment to joint creation and mutual success was clearly demonstrated during the progress of the 40,000m³ project.

During the construction of the lead vessel, S1083, an issue of elevated temperature in the vessel's shaft generator arose. Upon identifying the problem, the project team immediately took the initiative, forming a joint technical working group with the shipowner and the equipment manufacturer. The three parties conducted multiple rounds of analysis and finally agreed on a practical solution. Through coordinated actions, they expedited the delivery of necessary replacement parts to the shipyard.

More significantly, the shipowner Exmar already operates similar vessels. SOE's proactive identification and collaborative resolution of this issue not only strengthened the quality foundation for the newbuild but also resulted in a replicable technical optimization. This solution was subsequently applied by Exmar to upgrade the operation and maintenance of its in-service fleet of the same type. This collaborative problem-solving transformed a single technical issue into an opportunity for shared technical benefits and deepened trust, truly reflecting the core value of "win-win" in collaborative development.

Steady Progress, Planning Ahead: Powering the Green Voyage with a Diverse Order Book

Steel-cutting ceremony for Capital Gas's first 40,000m³ MGC carrier, S1111

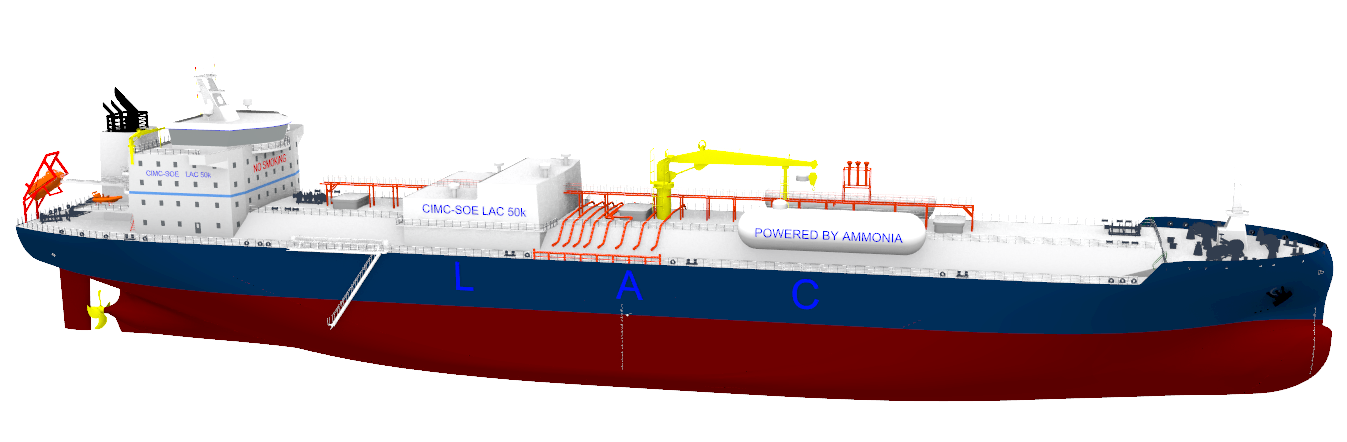

Rendering of the 51,000m³ MGC carrier

Currently, SOE's MGC carrier construction schedule is advancing steadily: Exmar's second 40,000m³ project (Hull No.: S1084) is nearing delivery; Capital Gas's four 40,000m³ vessels have also been successively initiated; and particularly noteworthy are the two 51,000m³ MGC carriers for Amon Gas, scheduled to commence construction in January 2027. These are not only the largest capacity gas carriers undertaken by SOE but also among the industry's earliest LPG carriers designed to use liquid ammonia as fuel. As a key candidate for zero-carbon fuel, liquid ammonia transport technology is a crucial piece of shipping's decarbonization puzzle. SOE's early move into this field demonstrates its acute awareness of market trends and underscores its corporate commitment to supporting the global shipping industry's green transition through advanced equipment manufacturing.

Gao Wenbao, Vice President of CIMC ENRIC and General Manager of SOE, stated: "CIMC SOE consistently leverages its long-established technological and manufacturing strengths in the global liquefied gas carrier sector to reinforce its industry leadership. In 2026, we plan to deliver 21 vessels, including 9 high-value-added gas carriers. Moving forward, SOE will continue with steady and determined steps, contributing its expertise to the green transformation of global shipping!"