Recently, Nantong CIMC Sinopacific Offshore & Engineering Co., Ltd. (hereinafter referred to as "CIMC SOE") has consecutively completed several critical milestones for cryogenic tanks. These include the delivery of two 1650 m³ LNG fuel tanks to CIMC Raffles Offshore (hereinafter referred to as "CIMC Raffles"), the delivery of one 7500 m³ LNG fuel tank to ZSCH Ship Co., Ltd. (hereinafter referred to as "ZSCH Ship"), and the commencement of construction on a 3400 m³ stainless steel C-type double-lobe tank for TGE Marine.

1. Successful delivery of two 1650 m³ LNG fuel tanks to CIMC Raffles

At the end of November, CIMC SOE delivered two 1650 m³ LNG fuel tanks (Project T149) from its East Area dock to CIMC Raffles. This high-quality delivery follows the successful delivery of a 2000 m³ LNG fuel tank project at the end of October, further solidifying the deep cooperation between CIMC Group companies in the field of clean energy equipment.

T149 project hoisting

The LNG fuel tanks delivered will serve car carrier vessels and are classed by DNV. During the project, despite the tight production schedule and stringent quality requirements, the project team leveraged their technical advantages, meticulously implemented production plans, and maintained efficient communication with CIMC Raffles to ensure smooth progress at every key milestone. Building on previous successes, this project introduced further optimizations in construction details, earning high praise from clients for design execution, production, and final hoisting and dispatch, showcasing CIMC SOE's commitment to lean manufacturing.

T149 project hoisting and dispatch #1

T149 project hoisting and dispatch #2

T149 project hoisting and dispatch #2

2. Successful delivery of the world’s first 7500 m³ stacked LNG bi-lobe fuel tank to ZSCH Ship

In early December, CIMC SOE successfully dispatched the third set (Project T156) of the world's first series of ten 7500 m³ stacked LNG dual-ear ship fuel tanks it built for ZSCH Ship. It will be installed on container ships constructed by ZSCH Ship.

T156 hoisting

T156 loading and dispatch

T156 loading and dispatch

During the construction phase, the project team optimized various specific processes based on feedback from the first two sets. For example, they made more scientifically reasonable arrangements for the sequence of some construction processes, enhancing the efficiency of connections between procedures and effectively shortening the entire construction cycle. Additionally, the team paid close attention to numerous detail issues discovered during the construction of the first two sets, making comprehensive improvements in the third set. Every aspect, from the external appearance of the fuel tanks to the installation precision of internal critical components, underwent meticulous inspection and optimization to ensure higher quality standards.

3. Commencement of construction for the 3400 m³ stainless steel C-type bi-lobe tank for TGE Marine

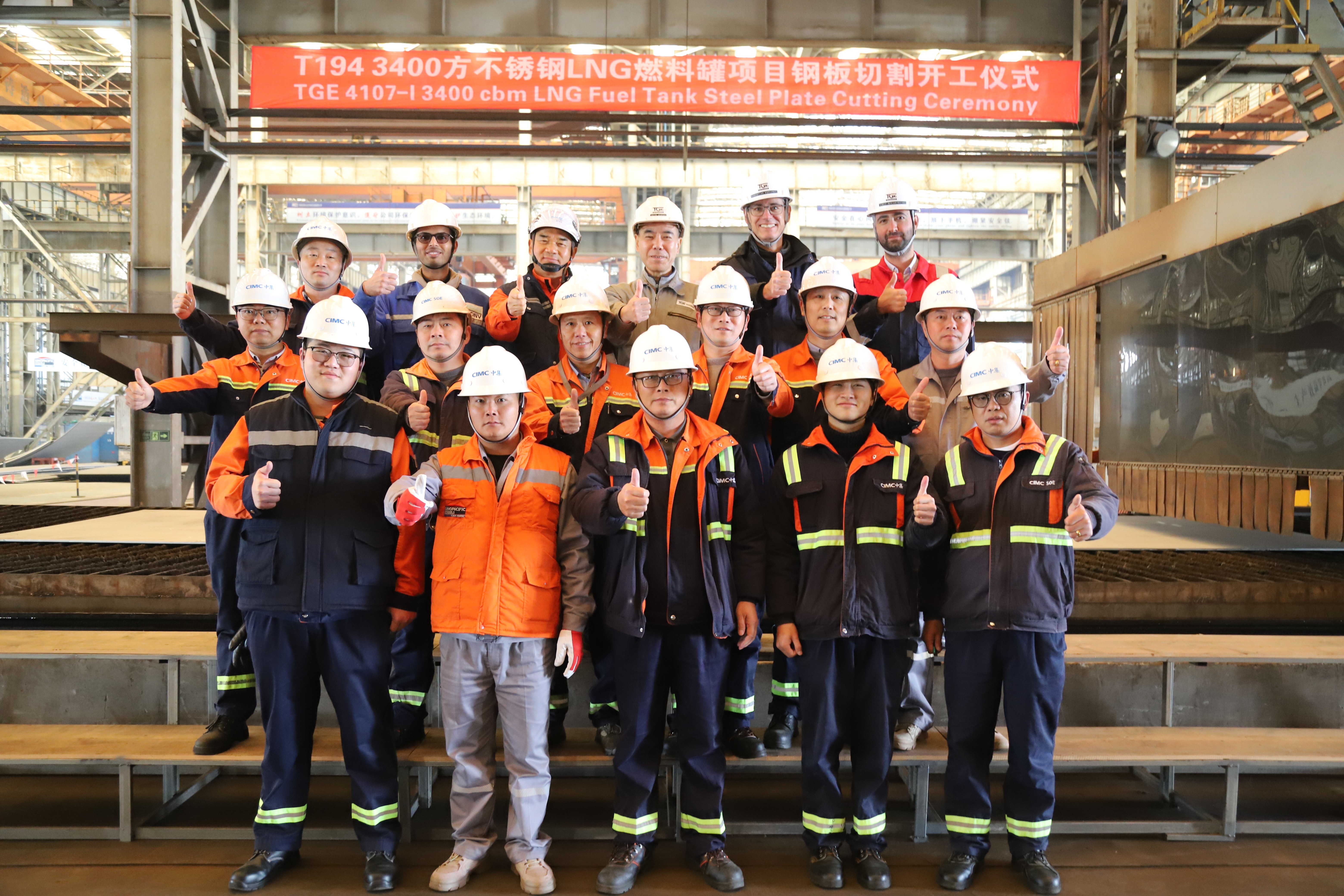

At the end of November, CIMC SOE commenced construction on the ninth set of 3,400 m³ stainless steel C-type double-lobe tanks (Project T194) for TGE Marine at the East Area. The plant manager of TGE Marine, Mr. Zheng Jianxiong, along with two liquid tank design managers from the German headquarters, attended the commencement ceremony, joined by representatives from DNV and members of the CIMC SOE project team.

T194 commencement ceremony group photo

At 10:58 AM on that day, the project officially started cutting operations. The T194 series project is part of the T119-T126 series (CIMC SOE's first stainless steel project), which will later be used on PCTC ships ordered from China Merchants Heavy Industry (Jiangsu) Co., Ltd. CIMC SOE independently completed the detailed design and production design of the liquid tanks, ensuring that the design, manufacturing, and acceptance all comply with classification society norms and requirements.

The recent completion of these important milestones once again demonstrates CIMC SOE's profound technical expertise and outstanding project execution capabilities in the construction of LNG fuel tanks. Looking forward, the company will continue to provide innovative and efficient liquid tank products to customers, actively promoting the development of the green energy equipment industry.